Manufacturing processes can be complex, costly, and challenging to manage on a large scale. Fortunately, industrial robots are making it easier for factories to optimize their processes, automating repetitive tasks and functions that humans have traditionally done manually. The increased efficiency of these robotic arms has revolutionized the manufacturing industry, allowing factories to produce high-quality products more efficiently than ever.

In this article, we’ll explore how an industrial robot arm works, its benefits to the production line and why it drives cost savings across businesses today.

Table of Contents

What Is An Industrial Robot Arm, And What Does It Do?

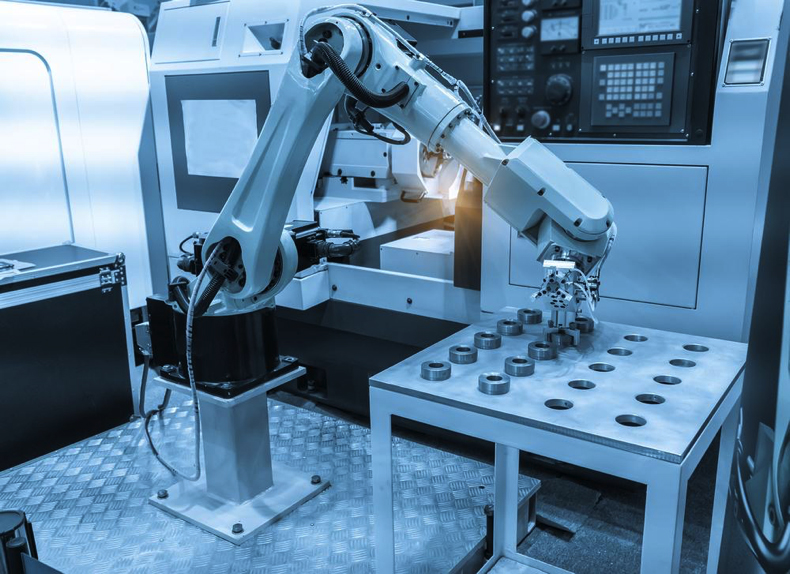

An industrial robot arm is a robotic system operating in manufacturing environments, utilizing programmed commands to perform specific tasks. The mechanical device consists of two or more joints known as actuators that move along coordinated axes and feature built-in sensors for detecting objects in their environment. Industrial robotic arms are used for lifting, welding, and assembling parts. Robot arms can also be found in other industries, such as logistics, warehousing, food production, and pharmaceuticals, among many others.

How Does An Industrial Robot Arm Make Manufacturing More Efficient?

Industrial robot arms make it possible to optimize the production of products by cutting down on human labor costs and increasing output. By automating processes typically done manually, industrial robots can increase productivity while reducing cost per unit produced. They can also be programmed to detect changes in product specifications or quality standards so that the production line consistently produces parts with the desired specifications.

Furthermore, their ability to complete tedious tasks quickly and accurately leads to improved safety conditions for employees as they no longer have to engage in repetitive manual operations.

What Are Some Other Benefits Of Using An Industrial Robot Arm?

Using an industrial robot arm brings many other benefits to the production line. For instance, they provide greater accuracy and consistency in product quality since robots can be programmed to perform specific tasks consistently and precisely. They also enable factories to quickly scale up production as robots can work simultaneously on multiple projects faster than human workers, making it easier for businesses to grow and expand into new markets.

Finally, robotic arms allow manufacturing companies to reduce energy costs by operating more efficiently than humans, leading to reduced carbon emissions and an overall smaller environmental footprint.

How To Choose The Right Industrial Robot Arm For Your Business?

The industrial robot arm that is best for your business will depend on the specific needs of your production line. Your choice should be based on factors such as the weight, size, and shape of objects to be handled by the robot and any hazardous environments in which it must operate. Additionally, you should consider what type of programming language and user interface you need for controlling the robot.

Industrial robots come in various sizes and configurations, so make sure to select one that meets all your requirements. It’s also important to factor in potential maintenance and repair costs when selecting a model to ensure that you can easily afford these services if needed. Lastly, talk with an experienced robotics engineer who can assess your needs and help you select the best robot for your business.

Are There Any Concerns About The Impact Of Industrial Robot Arms On The Workforce, And If So, What Can Be Done To Address Them?

Introducing industrial robot arms in manufacturing can potentially disrupt the workforce, especially if employees are not adequately trained to use them. To address this concern, businesses should consider providing ongoing training and support for their staff about robotics technology.

It will help ensure that workers remain up-to-date on safety protocols and better understand how robots can be used most effectively. Additionally, companies need to be aware of any potential job displacement due to robotic automation and take measures such as retraining or relocation assistance for those affected by such changes.

The Future Of Industrial Robot Arms In Manufacturing

Industrial robot arms are increasingly being used in manufacturing as businesses continually seek new ways to reduce costs and increase production. As robots become more sophisticated, their capabilities will only expand and lead to further improvements in efficiency. Additionally, advances such as cloud computing and artificial intelligence will allow for even greater levels of automation which could revolutionize the way factories operate.

Conclusion

Industrial robot arms provide many advantages to businesses, such as improved accuracy, scalability, and energy savings. However, companies must take steps to ensure the proper training and support of employees before introducing robots into their production lines. As technology continues to evolve and become more advanced, industrial robot arms will only become more prevalent in manufacturing processes worldwide.

Though a significant shift in business operations may be required for some companies, investing in this technology can help them remain competitive while also reducing environmental impact.